After installing needle and ball bearings and a new hardened steel shaft to pivot the voind robot arm, we noticed that the stepper motor shaft was presenting noticeable axial movement when the arm was being accelerated up towards an horizontal position.

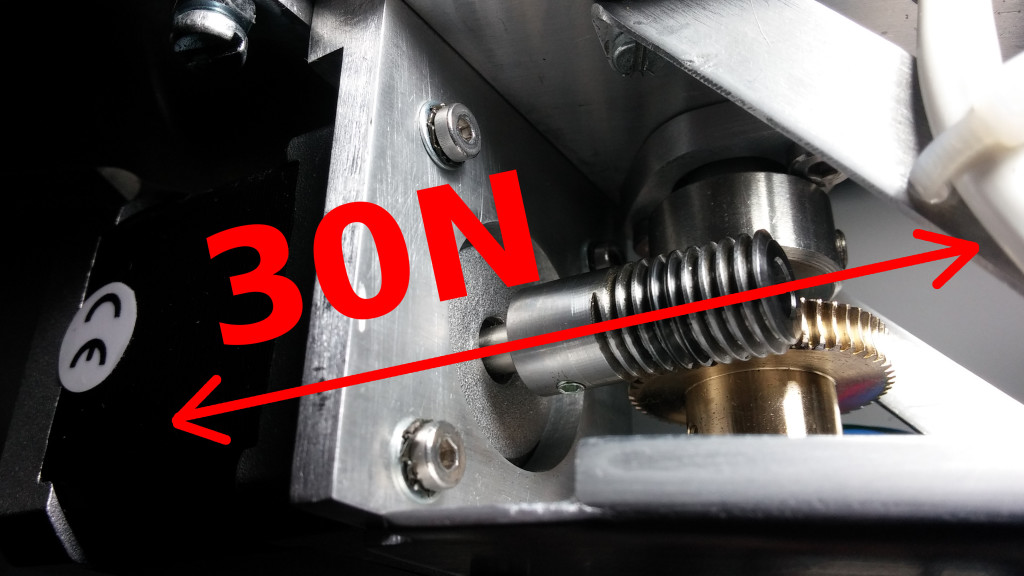

A quick calculation revealed the design flaw: the stepper motor is driving a worm/wheel which converts the significant torque of the arm into a 30N axial force on the stepper shaft, 3 times the rated value for this particular motor!

Luckily we discovered the problem before the motor internal bearings were completely destroyed! This was the reason why the robot was unable to perform any rotational arm movements when it was exhibited at the Lisbon Mini Maker Faire.

We then took some time to evaluate a solution for this problem. Two options were considered:

1. Compensate for the torque on the arm shaft using springs and/or a counterweight

2. Reinforce the axial maximum load supported by the stepper motor on its shaft

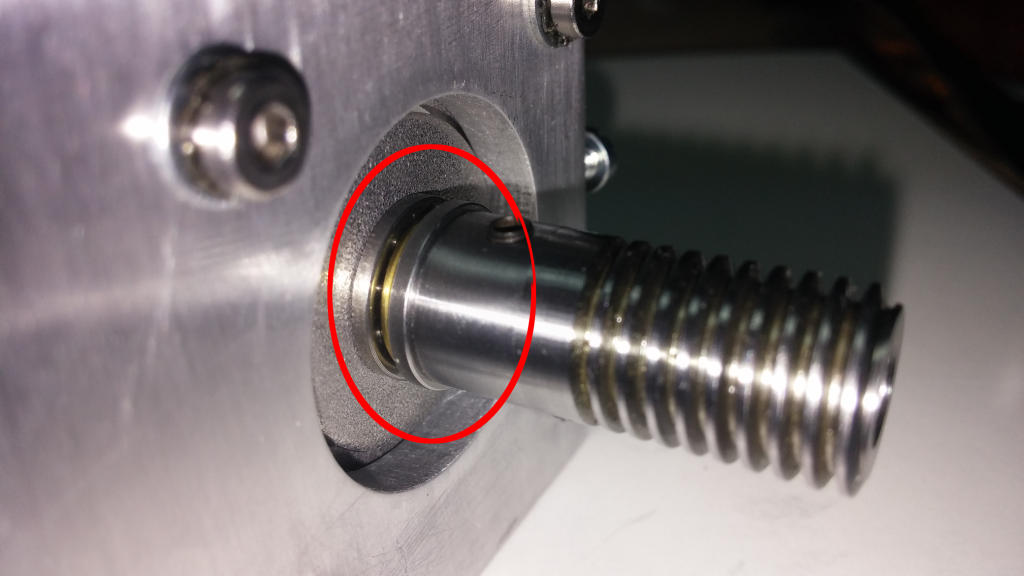

We chose to go for option 2 using a pair of miniature thrust bearings mounted directly on the motor shaft and pressing against the motor case on both ends:

Through careful adjustment we believe the axial load is now being entirely transferred to these bearings which are more than capable of supporting it leaving the motor with the sole task of driving the worm.