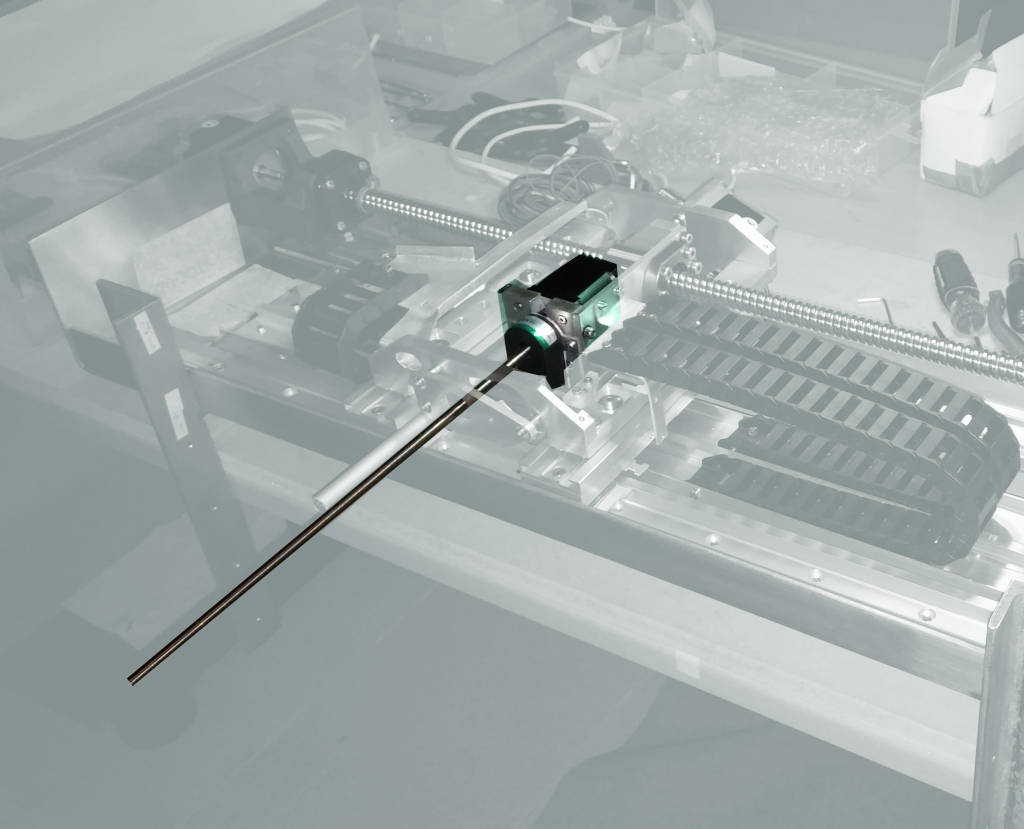

One of the motors on the voind robot is an External Linear Stepper Motor, more precisely an SY17STH0404-300A6.35X2X2-P1-EX. It has a threaded shaft engaging a threaded nut that drives the robot arm perpendicularly to the equipment face.![584[1]](http://www.voindnet.com/blog/wp-content/uploads/2014/05/5841.jpg)

This motor is conveniently supplied with a 30 cm shaft which should be more than enough for every application. However in our case we needed to cut the shaft shorter.

We first wrapped the motor in plastic film to protect it from any metal chips and used a small drill press vice to hold it firmly by the shaft, having wrapped it in a generous quantity of soft paper to protect the thread.

We then used a Dremel EZ456 cutting wheel to make an initial cut one centimeter outside the mark to be able to position the tool perpendicularly to the shaft for the final cut. To prevent overheating the shaft and motor we cut in 10 to 15 seconds intervals followed by 45 to 60 seconds periods of pause for cooling.

Interestingly, although the shaft seems to be made from stainless steel, not a single spark was produced during the cut…

Ideally we would have a 6.35×2 nut screwed in to help restore any damaged thread start by removing it after the cut. However we did not have any suitable nut around and we had to resort to a magnifying glass and some fine sand paper to make sure the threads started smoothly.

Finally the motor with the correct thread length and ready for assembly.